Factory Machine Automation

Objective: Install a device Jute Lab’s jute stitching machine. This device was intended to automate the designing process of the machine, where a manual worker would have to push and pull a trigger, in order to change the stitching direction.

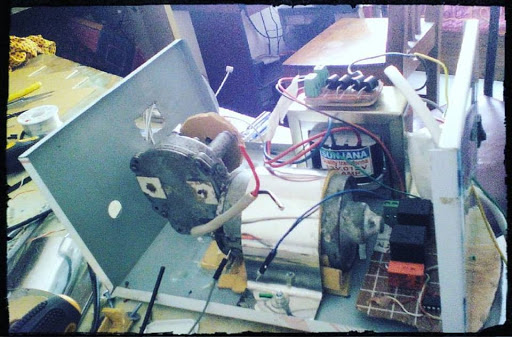

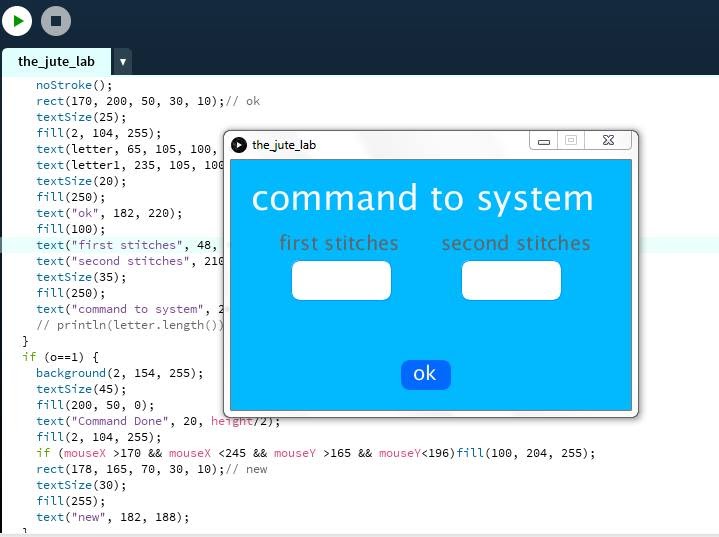

Approach: This was a particularly difficult project as manually counting the number of stitches in an accurate fashion is tedious. I designed this device in three main sections- the trigger pulling mechanism, custom-made sensor to count the number of stitches, and the software user interface to take input. The custom made sensor used a high speed laser, and LDR, to detect each stitch. In order to make the trigger pulling mechanism, I used the same custom motor driver design to control the high current motors. Finally, I used Processing to program the user interface. Installation of the device took two days, and we had to carefully move the device through rough roads and ferry rides to reach the factory site.